Top 5 Benefits of Laser Scanning in Construction

This article was originally published on LinkedIn Pulse

How many times have you been on a job site where the ductwork runs into the structure or the electrical runs into the fire protection? Project hiccups due to inaccurate site blueprints happen far too often and lead to coordination issues across field teams. How can you prevent these costly interruptions? Enter 3D scanning technology.

3D scanning has taken off in the world of design and even been used in aerospace and automotive manufacturing, but has been underutilized in the construction industry. While there are many more benefits to the technology, here are the five main reasons 3D scanning makes general contractors and project managers stand out in such a crowded space.

Improved Accuracy

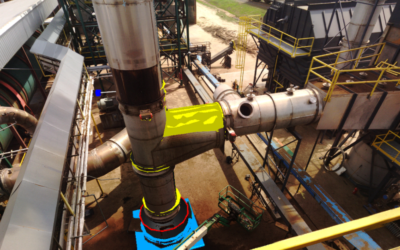

With a simple non-harmful laser scan, general contractors and project managers achieve EXACT site conditions (down to the millimeter) that their trade teams can then rely on to make coordinated and accurate construction project plans. With the physical measurements of the space and objects within, field teams can ensure that all the manufactured components (ductwork, electrical, waste pipe etc.) fit together on the first try instead of having to go back to the drawing board. Goodbye costly work order changes.

Risk Mitigation

Using outdated measurement tools like a tape measure can sometimes require teams of 4-6 field workers to be placed in precarious environments and increase time on-site, leading to higher injury risk. With 3D scanning, there is no need for scaffolding or ladders. One laser scanner can capture the precise measurements of high ceilings and ductwork far above human reach. With one person armed with a laser scanner, you significantly increase your site safety.

Increased Speed

Laser scanning has been shown to significantly reduce the time it takes to measure construction sites, sometimes by even 75%! By capturing millions of data points per second, one laser scanner can do in a day what would take a team of 2-6 one week.

Reduced Cost

If the time spent on-site to measure goes down by 75%, so does the cost. But the cost savings aren’t just from man-hours saved. Inaccurate site measurements can cause additional expenses in equipment rentals, man-hours, additional trade materials, and project delays, adding up quickly. With the exact site conditions provided by the laser scanner, teams can plan effectively and prevent these costly disruptions.

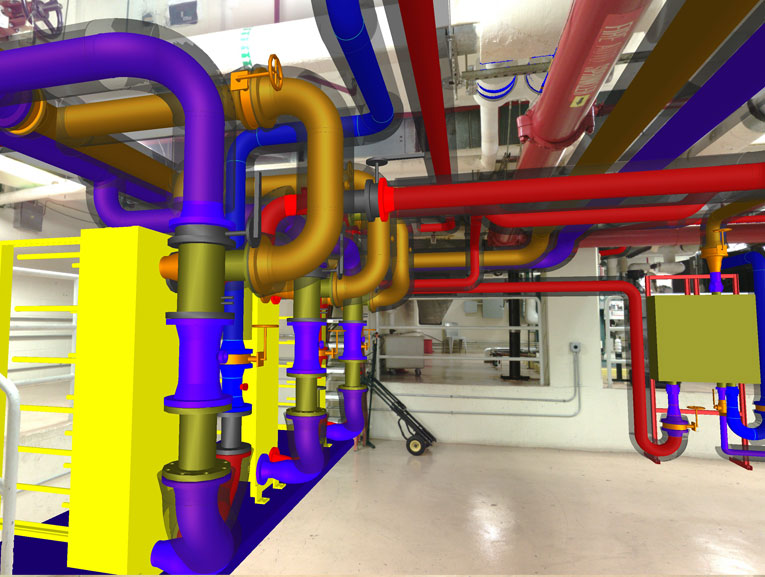

Better Coordination

In our era of remote work and connectivity, teams may be working together across states or even the country. On-site visits in these cases can become an expensive time-drain. Laser scans can be used to create a 3D virtual site overview so no matter where your team is located they have access to the smallest site details and complexities. These are incredibly helpful for coordination.

If you are a contractor looking to differentiate yourself in our highly competitive industry, or looking for a way to save time, and money, scanning technology may be your answer. To find out more information on how laser scanning can be applied to the construction site workflow, take a look at our recently published blog post.

If you have further questions feel free to reach out on LinkedIn or shoot me an email at j.lim@caddjm.com!

Supercharge the project lifecycle with 3D Scanning.